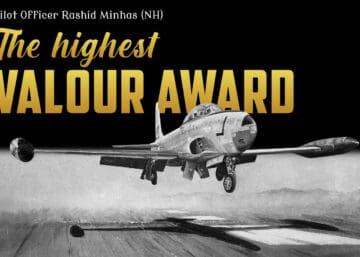

A lot of people at the LA (Light Aircraft) department in Aircraft Manufacturing Factory (AMF) have immense passion for what they do and mass-producing Super Mushshak is what they do best. This piston-engine trainer plane is a product of experience, constant changes and improvements, innovation, and is dedicated to meeting all service conditions. Built from ground up, the Super Mushshak is an easy to maintain and simple to fly training / utility aircraft. With origins dating back to early 1970s, it has stood the test of time and has become the dominant primary flight trainer in the world.

Today if you Google to find the countries indigenously producing aircraft, you will come across few. If you refine the search further to learn how many air forces of the world are manufacturing aircraft at their own, you will be surprised. It’s only Pakistan Air Force….By all standards it is no mean feat. The achievement is outstanding and, indeed, a matter of pride for the nation. However, laurels are not attained over night. Behind the scenes, as always, there is a saga of commitment, perseverance, hard work and, above all, faith; and the men and women of Pakistan Aeronautical Complex (PAC) have demonstrated it for decades.

Over time, the PAC folks are repeating their successes year after year. Here a dream team have been manufacturing the Super Mushshak (Urdu word for ‘The Proficient’) for more than four decades. It is one of the longest running training aircraft manufacturing programmes in the world. The requirements are daunting – to produce an aeroplane that has high performance, enhanced manoeuvrability, durability, maintainability, and most importantly is safe for flight training.

The Super Mushshak is one of the most dependable trainer aircraft flying today, embedded with state-of-the-art systems needed for imparting quality training. A modern training aircraft must possess an engine a pilot does not have to worry about and advanced avionics suite that optimizes pilot performance in the cockpit. ‘Made in Pakistan’ Super Mushshak has it all.

“Kamra did not become the hub of aircraft rebuild and manufacturing overnight. Thousands of skilled workers employed, trained and full of commitment and passion; hundreds of thousands square yards of hangar space housing cutting edge production and testing machines / equipment, miles of cables to operate those heavy machines, and tarmacs, runways and taxi strips provided, all on more than ten square miles of stretch is what makes Kamra an epitome of Aviation Manufacturing. We are proud of our products, Pakistan is proud of it”, elaborates Air Marshal Syed Noman Ali as he discusses the products, services, and projects of the four factories and other constituent setups of Pakistan Aeronautical Complex.

Back at the Aircraft Manufacturing Factory (AMF) where these Super Mushshaks are manufactured, a dedicated team of aeronautical engineers, technicians and researchers, under the supervision of AVM Shamsul Haq MD AMF, are clocking long working hours to meet time-compressed production targets. Explaining the value proposition of Super Mushshak, AVM Shams believes that this trainer plane is ideal for the mission of training ab-initio pilots of air forces world over. This little bird has growth potential engineered into it. It can even operate out of small unpaved airstrips. It has just been a year after AVM Shams took charge as the MD, AMF made a breakthrough by winning a contract to supply Turkey with 52 Super Mushshak, beating America’s Cirrus and Germany’s Grob, two of the biggest names in the industry.

“It is a great achievement, and we are proud of it” the AVM said.

This is not all. The contracts signing ceremonies for the sale and support of Super Mushshak aircraft have now become a routine at PAC Kamra. Most recently, the aircraft added a new customer, Zimbabwe, that wants a dozen new Super Mushshak for its air force and it wants none other than AMF to build them.

You look at everything and realize just how much goes into the production of the plane and the hours it takes for the finished product to roll out the doors. Powered by the American Lycoming engine, the Super Mushshak is built like a model plane. It all starts by machining, bending, and forming over 2,000 aluminium piece parts – sheets, beams, cylinders and every form of this light weight metal. This is the first step of manufacturing. Aluminium sheets are cut to proper sizes for handling in the machining centres, presses, and forming machines. Since these planes are to be flown by air forces over different terrains, over salt water, in the desert heat, and cooler environments, around half of the world, individual parts have to be treated to protect them from the harsh environmental effects. Through its ingenuous efforts to keep Super Mushshak relevant in evolving aerospace manufacturing landscape; AMF has replaced a large number of aircraft’s aluminium structural parts with composite materials. The facility to manufacture, mould and assemble these composite material parts is one of the finest in Pakistan.

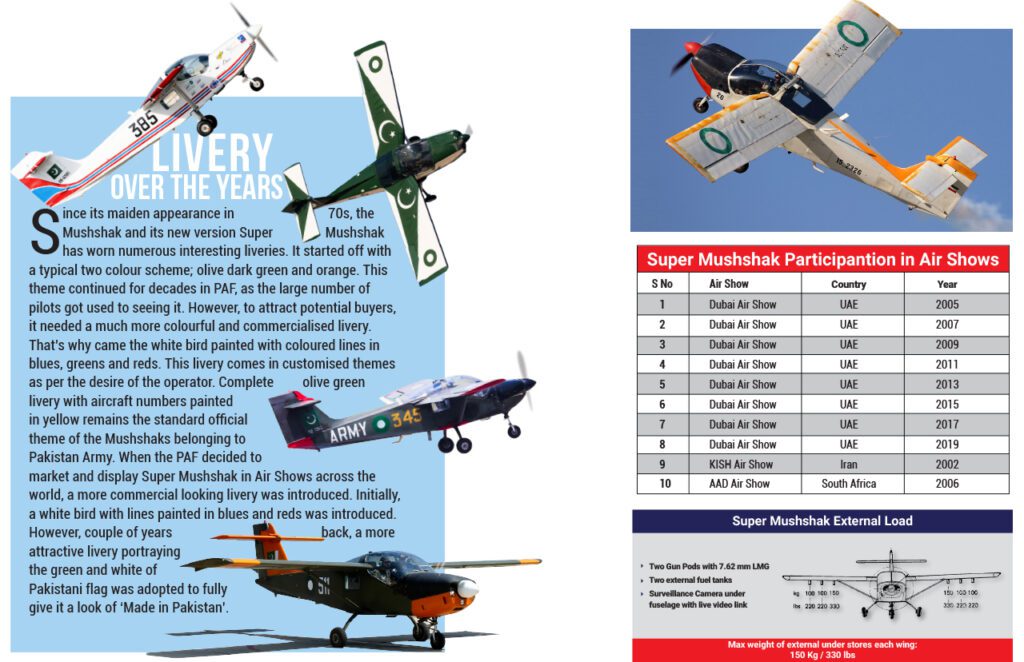

These parts are put together through high-precision structures, called assembly jigs to manufacture different structural assemblies of the aircraft. You can witness the aircraft taking shape when fuselage is joined with wings and other structural surfaces. The 6 cylinder engine is mounted through an intricate but clearly defined process by hugely experienced technicians. IPAD looking fuss-free glass cockpit, radio and other delicate equipment are installed and propeller is added in station to station assembly process. The canopy, which gives pilots a 360 degrees view, comes on next. All of it is formed and assembled by hand due to complexity of involved processes and the need to exercise engineering intervention at different stages of work. It is a perfect example of ‘Made in Pakistan’ product where knowledge and skill of trained manpower is of paramount importance. The aircraft then rolls over for a customized paint job. With all done, the team which produced it, pushes the brand new Super Mushshak out of the hangar to mark its rollout.

Back in the early 1970s, the prospect of setting-up facility for manufacturing of Mushshak aircraft was viewed with some scepticism. But the planners at PAC Kamra had the vision to take-on this challenge. “PAC was fortunate to have pioneers like AM Shaikh Saeed who played an instrumental role in laying the foundations of this complex that has today transformed into a true aviation city. It was on the wings of their dreams that most of the aircraft in the PAF fleet continue to take flight”, reminisces Air Marshal Syed Noman Ali while paying tributes to his predecessors. The Chairman also underscored the pivotal role played by PAC for factory-level maintenance of PAF fleet, and its aircraft and avionics production capability.

The Mushshak catapulted into PAF history in 1974, when the AMF rolled out the first 15 of these trainer planes built from semi knocked down kits, acquired from SAAB SCANIA of Sweden. After successfully producing 92 Mushshak aircraft, AMF acquired the status of Original Equipment Manufacturer (OEM) in 1982 and started manufacturing Mushshak indigenously, which were inducted by both PAF and Pak Army in sizeable numbers. By 1995, a new vision started to materialize- transformation of Mushshak into Super Mushshak aircraft.

The more agile Super Mushshak flew its first flight in August, 1996. With its six cylinder Textron Lycoming 260 HP engine, the aircraft could now operate with cruising speed of 135 knots, around 30 knots faster than the original version. Another improvement was the cockpit’s air conditioning system which came as a blessing for the countries where the temperatures regularly reached 50o C in summers. Approximately, 70 Super Mushshaks were needed by PAF after the new variant became available. However, rather than acquiring brand new aircraft, the upgrades were simply retrofitted in the original airframe. The first upgraded aircraft was handed over to PAF Academy Risalpur on 16 May 2001 and within a short span of five years, all the PAF Mushshaks were upgraded to the more agile and advanced Super Mushshak configuration.

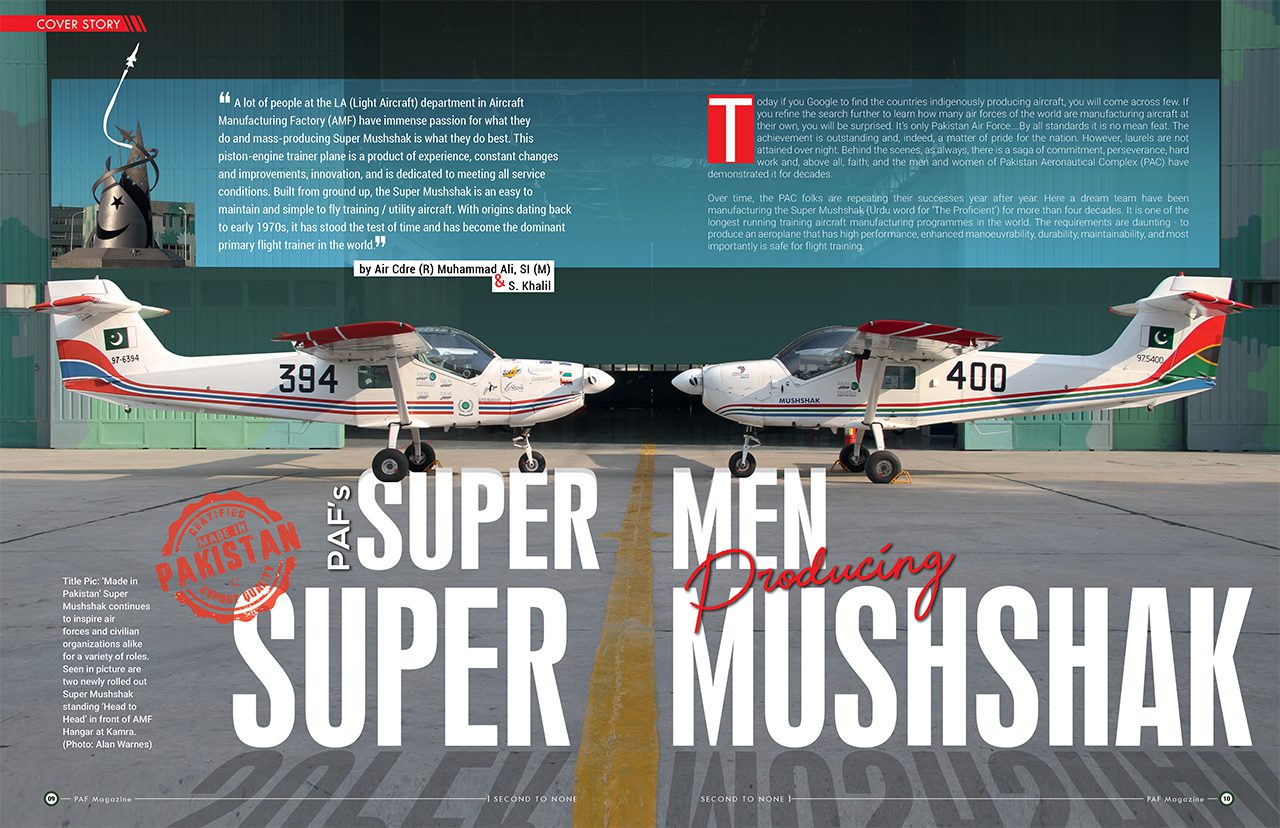

Then came the stage where PAF senior leadership decided to showcase the indigenously manufactured Super Mushshak to air forces and civilian entities around the world. Initially, the task appeared impossible; however, with intensive marketing of the aircraft, the results started to appear. In the first phase, the strategy was to market the aircraft in Middle East only. The efforts bore fruit and PAC won the first ever overseas military sale contract from RAFO (Royal Air Force of Oman) in late 2003. There on, there was no looking back. The marketing strategy opened up to other continents as well and led to sale of Super Mushshak to a large number of countries across the world. Saudi Arabia, Turkey, Qatar, Nigeria, Iran, Azerbaijan, Iraq, Syria, South Africa, Oman, and Zimbabwe are some of the countries that have chosen Super Mushshak to train their ab-initio pilots in this modern trainer. And the list of satisfied customers is growing.

“Before the acquisition of Super Mushshak we had a Diamond Trainer which had limitation of not performing aerobatics and it could only be used for training civilian pilots. However, with the induction of these (Super Mushshak) aircraft from Pakistan we have overcome these problems. The Super Mushshak is now training our air force cadets at Academy and its induction has significantly reduced the period of training for the pilots”, said the Director Public Relations of NAF while talking to media back in 2019.

Post 2016, the conventional analogue dials were replaced by a sophisticated glass cockpit. This was done to bring Super Mushshak at par with premier trainer aircraft worldwide. The glass cockpit comes with two distinct configurations to select from; Garmin 950 and Dynon Aviation suites. Borrowing heavily from renowned G1000 glass flight deck system, the G950 is a seamlessly integrated package that makes flight information easier to scan and process. It has been acquired by majority of metro liners and commercial aircraft companies and has been integrated into Super Mushshak by PAC technicians. The other variant Dynon aviation suite has also been incorporated. This gives variety of choices to potential customers to choose from. AMF has now integrated the Genesys avionics suite on Super Mushshak aircraft which has exponentially enhanced the ease of operations for the operators with additional options.

“Today, AMF can easily roll out 20 Super Mushshak aircraft a year. The goal is minimum fuel consumption, maximum range, product of precision workmanship and expertise” said Air Cdre Javed Haider Khan, Deputy Managing Director at AMF.

After the Super Mushshak is built, AMF’s job is not yet done. The plane has to be tested by both ground and flight crews. The extensive flight testing of aircraft by the AMF, has and will be of vital importance. It also highlights the role flight test pilots play in the acceptance of aircraft by the air forces. The judgement of top ranking test pilots often become the basis for important decisions and modifications, which helps in making constant upgrades to the aircraft. Often, in the twin seater, someone who can help the pilot find out answers, will fly along – some one like a flight test engineer.

The Mushshak has logged one million plus flying hours around the world. While its primary customer remains the PAF, Pakistan Army also operates a substantial number. Other than the basic roles, Pak Army utilises these birds in wide range of army co-operation missions which includes Forward Air Control, Forward Area Support with droppable supply, Reconnaissance, Artillery Fire Observation, Camouflage Inspection, Border Patrol, Liaison, Target Flying and target towing for training of ground units etc.

“The Super Mushshak excels in training potential pilots at the primary flying training levels”, said Super Mushshak test pilot Wg Cdr Majid Ali. The factory continues to refine the design, easing pilots’ natural transition to advanced weapons systems. “There are no problems with the roll rate. Barrel rolls, loops, the Super Mushshak performs them all including stall and spin manoeuvres that are basic requirement for most pilots learning” he added.

While complimenting this ageless bird, equipped with super composite parts and advanced digital flight control system that let a pilot do what he / she wants, Gp Capt Usama Salar Sufi (Super Mushshak test pilot) eagerly describes its inverted flight feature and its ability to perform at +6 to -3 Gs, a rarity in this class of aircraft. And while he admires its forward swept wings that gives the aircraft enhanced efficiency, Chief Test Pilot Gp Capt Nusrat Abbas complemented the improved safety feature which allows the aircraft to auto-recover from a spin. And that’s not all. Being the aerobatics pilot, Gp Capt Nusrat is in love with this highly manoeuvrable bird. “It is a little plane which is getting more fame due to its impressive manoeuvrability at international air shows. It gives us a feeling of pride when we fly this ‘Made in Pakistan’ aircraft”. Beautifully painted in green and white theme, the aircraft prominently displays Pakistan’s ‘crescent and star on its fuselage. “It gives you an extra dose of adrenaline when you fly in front of cheering crowds that too in foreign lands” adds Gp Capt Nusrat. “The usual aerobatics performance lasts for almost ten minutes during which we have to demonstrate the performance to the general public and potential buyers alike”, he emphasises.

The Super Mushshak has a hard task. It has to continue to win fights against the likes of it. Which is why everything progressive at the AMF, is invested in modernization. When the PAF first built the Super Mushshak, it was for the endurance and versatility of this little beauty that convinced the air force to put a production order for it. Fast forward few decades the scene has changed. Now the world is looking for state-of-the-art avionics, design and above all safety.

“It is the grace and safety of the design that captures the affection of those who fly it”, concluded Gp Capt Nusrat Abbas…